MaxiCode

MaxiCode was first patented in 1992 as a code for high-speed conveyor sorting. The original name was the Dense Code, which was later changed to UPS. The last established name was MaxiCode.

Maxicode is a two-dimensional barcode symbology used by United Parcel Service on packing lists for international addressing and sorting of packages. Instead of using strips, MaxiCode uses points located in a hexagonal grid or a honeycomb structure consisting of 888 information-bearing cells. Cells surround a "target" or "bullish eye" in the center, which allows the scanner or camera to find a symbol. Although MaxiCode is limited to about one square inch, they can be linked up to eight times for a longer message, called a "composite tag."

Maxicode bar codes have a fixed size of 1.11 x 1.054 inches and can store up to 93 data. In addition, there is the possibility of correcting errors, so the barcode can be read if damaged. The built-in error correction is based on the Reed-Solomon code. Since most such barcodes are on packages, they must be resistant to damage. Error correction allows code corruption up to 1/8 of a part.

Each Maxicode barcode includes two main messages: primary and secondary. The primary message includes a postal code, a country code and a class, and the secondary message contains address information.

To read the Maxicode barcode, you need a 2D barcode scanner, preferably one that emulates the keyboard and is powered by a USB port, so you do not need an external power source.

An important application of MaxiCode is the marking of packages, pallets, etc. In this application, MaxiCode can be a portable data file that moves with the package. It ensures the availability of critical information at any time when the goods are being processed.

MaxiCode was developed for inclusion in the existing manifest of delivery systems. Compact size means MaxiCode allows to avoid full or partial redesign of the label. Ultimately, MaxiCode can be used to replace symbols of lower density, such as linear barcodes.

One of the key features of MaxiCode is that it can be located and read at high speeds in a large field of view. This means that MaxiCode should be considered for integration into automated materials handling systems.

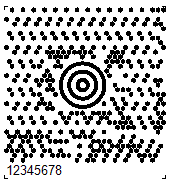

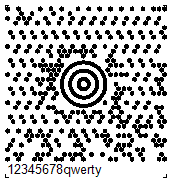

Starting with version 2017.03.01 FastReport.Net provides the barcode MaxiCode. Let's see how it looks:

In the center of the code, there is a special circular mark in the form of a target, to recognize the center of the barcode by the scanner. As you remember, the code can contain text data:

The advantage of this code is that it allows to encode sufficiently long numeric-alphabetic data and provides high read speed. This makes its use very promising in many industries.